- Homepage

- Brand

- Condition

- Manufacturer

- Material

- Alloy (4)

- Alloy Steel (11)

- Aluminized Steel (5)

- Aluminum (20)

- Cast Iron (2)

- Fabric (9)

- Leather (20)

- Magneti Marelli (2)

- Mercedes-benz (3)

- Metal (5)

- Needle Felt (4)

- Plastic (20)

- Polypropylene (pp) (2)

- Polyurethane (4)

- Rubber (18)

- Rubber, Plastic (2)

- Stainless Steel (29)

- Steel (22)

- Steel Sheet (4)

- Wood (3)

- Other (3678)

- Model

- 14 Oxrock (2)

- Ej8401 (2)

- For Mercedes-benz (4)

- Mercedes Viano 639 (2)

- Multi-spoke Wheel (2)

- Oe / Oem (13)

- Sprinter (2)

- Vans Vito (2)

- Viano (6)

- Viano (w639) (2)

- Viano, Vito (11)

- Viano, Vito - 639 (4)

- Viano|vito (6)

- Vito (8)

- Vito - Viano (03 10 (2)

- Vito / Mixto Van (2)

- Vito / Viano 2014+ (9)

- Vito / Viano W639 (5)

- Vito, Viano (7)

- W639 W906 (2)

- Other (3774)

- Type

- 5 Rayons (9)

- Amortisseur (10)

- Arbre à Cardan (11)

- Drive Shaft (6)

- Feux Arrière (6)

- Front Headlights (12)

- Headlight (14)

- Headlights (7)

- Injecteur (11)

- Jeu De Roues (8)

- Marchepied (10)

- Muffler (5)

- Phare (8)

- Silencieux (7)

- Steering Wheel (12)

- Tail Lights (6)

- Vehicle Specific (5)

- Wheel Rim (10)

- Wheel Set (6)

- Wheel Shaft (6)

- Other (3698)

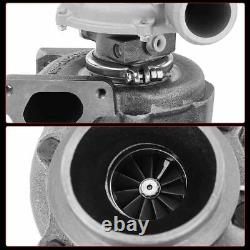

Turbocharger for Mercedes-Benz Viano Vito Mixto Bus W639 2.2 CDI 03-14

You can find your spare parts. Turbocharger for Mercedes-Benz Viano Vito Mixto Bus W639 2.2 CDI 03-14.

Attention: Important notes on the installation of a turbocharger. To avoid installation errors, APM recommends that the goods be installed only by a specialized workshop. Repair the cause of the malfunction and damage of the old turbocharger. Before starting the installation, the following parts near the turbocharger must be checked for dirt and density. Discharge and supply lines on the turbocharger.

Possibly a soot particulate filter. Engine oil, oil filter, and air filter must be renewed when changing the turbocharger. Before connecting the oil supply line, the turbocharger must be completely filled with clean engine oil through the oil inlet hole. The oil lines to the turbocharger and all flange and connection seals must also be replaced. For some brands, the intercooler must also be replaced according to the installation instructions.

Liquid sealants must never be used. After commissioning, check the tightness of all air, gas, and oil lines. The air intake and exhaust system and the intercooler must be cleaned. It must be ensured that the system is free of chips, dirt, corrosion, oil, and other foreign bodies or substances.

After installing the turbocharger, the engine must be restarted. Then let the engine idle for 30 seconds before applying a load.

We would like to draw your attention to the fact that warranty and/or liability claims against APM Autoteile GmbH cannot be considered if the turbochargers are installed without adhering to the above installation instructions and this alone causes damage.